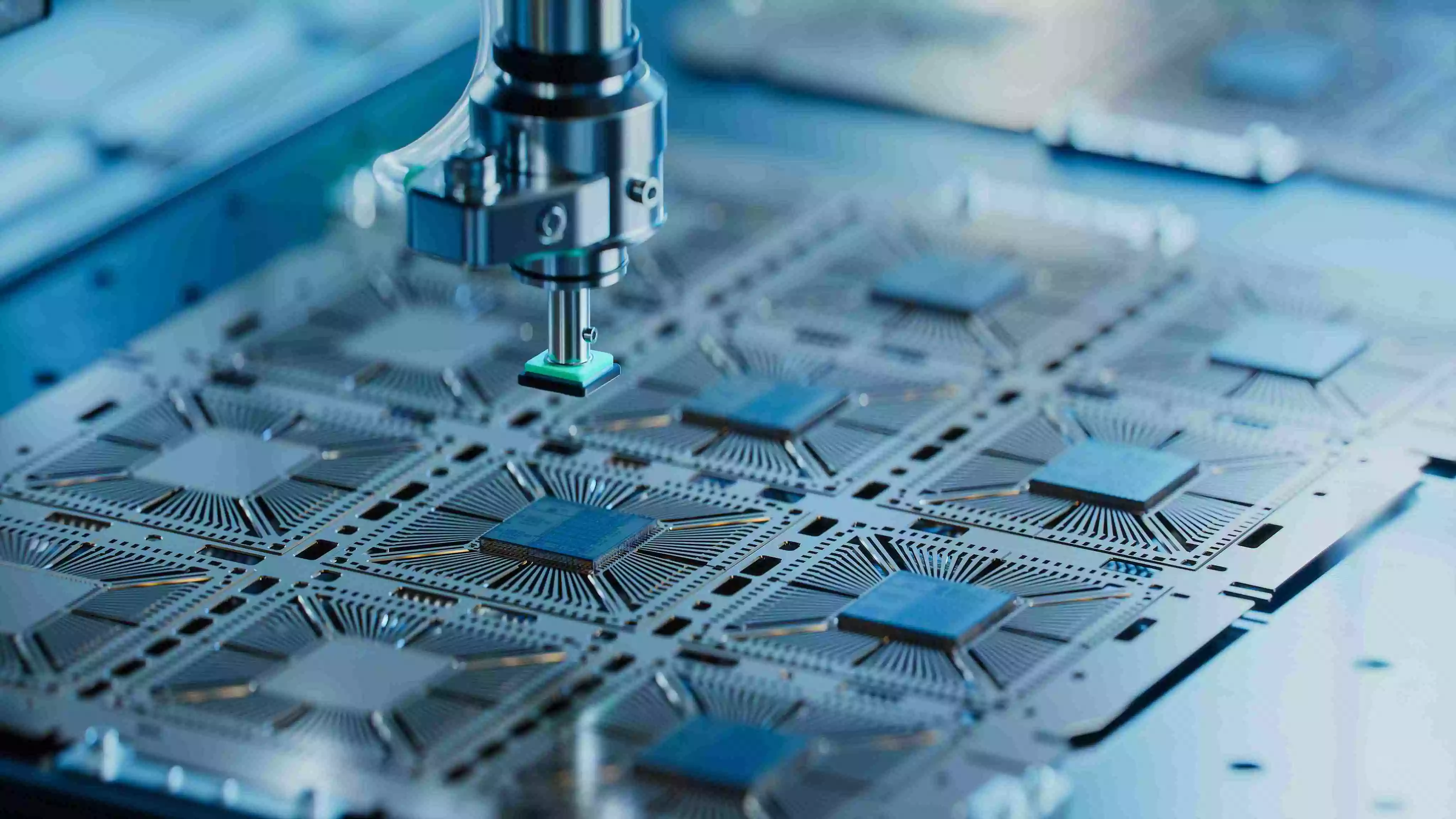

Semiconductor Industry Induction Heating

The production of high-quality semiconductor crystals requires a consistent and dependable heating source. Induction Technology Solutions is a preferred choice for supporting the crystal growth process. We offer advanced systems, individual components, and the expertise to create, implement, and support your induction heating for semiconductor crystal growth.

Why Induction in the Semiconductor Industry?

Induction has proven itself as a clean noncontact heating method that offers efficiency, safety, speed, and precision. Those qualities are critical to producing semiconductor crystals that meet strict quality standards:

- Homogeneity: Uniform crystal structure and composition

- Purity: The lowest possible levels of carbon, oxygen, and other impurities

- Performance: Consistency in structure, composition, and purity to ensure proper conductivity and overall performance.

With this in mind, we provide best-in-class solutions in induction heating for crystal growing applications

Why Induction Technology Solutions?

We will gladly work with you to prepare for Boeing audits. Our systems measure the temperature of the wire, verifying that the part has reached the target temperature, using dual-color optical pyrometers. The induction power supply’s settings (power, temperature) are stored in our data logger and can be recalled by work order and downloaded as a .csv or, using our proprietary software, you can see the data graphically. Verified, repeatable, logged results, every time.

Induction Heating Generators

-

Our SA/80 Generator Series includes models ranging between 25 and 150 kilowatts. As optimal heating sources, these induction heaters are fully factory-calibrated and deliver stable output. Other features include a data logging function, integrated timers, real-time monitoring, and a user-friendly interface.

Pyrometers

-

Precise crystal temperature monitoring is also key. Our optical pyrometers help accomplish this in a couple of ways. Besides allowing you to directly track the crystal's heat level, they can serve in a closed-loop heat control circuit. Just set the temperature, and the pyrometer can adjust the power supply output.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service