Induction Soldering Applications & Equipment

Our patented, small-footprint, solid-state induction soldering equipment is perfectly adapted to induction heating of smaller parts such as printed circuits, radio frequency connectors, or solar cells. Our Series 900 heaters offer greater than 95% power efficiency, providing for very high precision, fast, repeatable results for many induction soldering applications.

Specialized control equipment units manage all soldering working phases in a closed-loop control system that can run, learn, and recall the parameters set by the operator. The control units manage a motorized tin wire feeding system, whose parameters can be set for quantity, direction, speed, and feeding force.

What is Induction Soldering?

Induction soldering is a soldering technique that uses electromagnetic induction to heat metal components to the soldering temperature. By passing alternating current through an induction coil, a rapidly changing magnetic field is generated, inducing eddy currents in the metal, which in turn produce heat. This localized heating ensures precise and efficient soldering of components while minimizing damage to surrounding materials. Induction soldering is widely used in industries requiring high-quality solder joints with minimal heat transfer and precise control over the soldering process.

Benefits of Induction Soldering

It offers benefits such as precise control over heating, faster processing times, consistent soldering quality, energy efficiency, cleanliness, versatility, and improved safety compared to traditional methods.

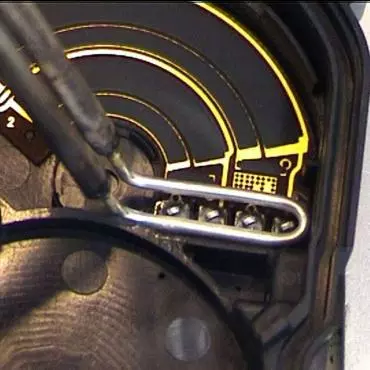

The Series 900 Induction Heaters in Action, Soldering Circuit Boards, etc.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service