Induction for Carbide Tipping Applications & Equipment

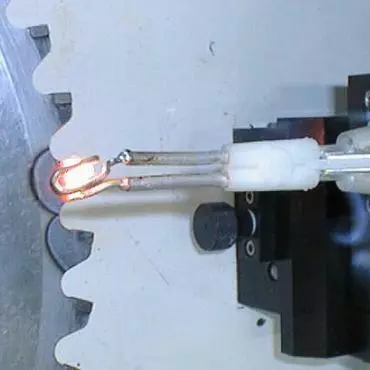

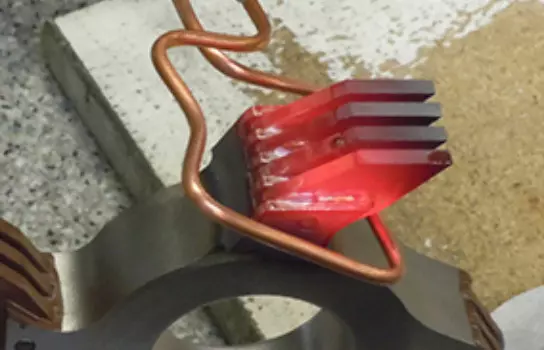

Induction heating for Carbide Tipping, or Carbide Brazing, offers many advantages over the torch brazing method. Take the manual labor and guesswork out of torch brazing and move to safe, effective, cost-efficient induction carbide tipping equipment to facilitate your process. Apply localized induction heating to just the brazing joint.

Carbide Tipping using Induction brazing offers key advantages over flame torch brazing

- No open flames, no more need for using Oxy-Acetylene torches or storing flammable gas tanks. Induction is clean, flameless, safe, and it is considered as a Clean way of brazing process.

- Localized heating: Precise “useful” heat can be focused only to the required joints to be brazed – particularly useful for carbide tipping. The metallurgical properties of the hard metal and cutting tip are safeguarded as long as the direct heat is focuses on the Steel and on the carbide itself. Overheating the carbide may cause thermal shock which would in turn cause cracking in the material itself.

- Consistency & Repeatability Braze after braze without having much torch-brazing skills. All brazed joints have heat applied evenly, and the brazed results are repeatable. No more over-heating or burning your workpiece! Our Induction Heaters offer extremely accurate temperature control, allowing the heat to be localized at the soldering area only, and safeguarding the metallurgical properties of the hard metal and cutting tip.

- Automation: Feeders, placement, heating – all can be automated cost-effectively. The alloy distribution can be applied using wire feeders, at a very predetermined precise dosage, having diameters from 0.3 mm to 1.5 mm. The quantity, speed, feed force, and times of wire distribution are completely programmable by you.

- Quick/Instant On features make induction energy and cost efficient. Full useful Power is available

on demand. - Brazing can be done in an atmosphere, using for instance Argon gas without using Flux for a nice clean braze – no post-cleaning required because Argon as a natural “scrubbing” agent which can clean the braze joint braze after braze.

- Much Faster than manual torch brazing.

- Replicable: Using our optional Master Controller V3+, you can control for Power and Temperature, or Power and Net Heating Time Presets for each braze joint diameter. Use the Controller’s “Quick Access” menu to pull up all the Presets for required braze joints prior to the day’s production run.

Return on Investment

- There are no user consumables. When properly maintained, the heating coils do not degrade over time. Buying coils is a one-time investment; additional coils might be needed for spares or for a new application, but that’s it – no continuously buying Oxy-acetylene tanks.

- Our affordable, compact, and energy-efficient Induction Heating Systems are a one-time investment; highly reliable and dependable design enables the generators to operate for many years to come.

- The Induction Generators can power-up immediately, no warm-up required. This means that you can leave the generator in stand-by mode without drawing any significant amount of Current from your factory Input Voltage Supply.

- An efficient cooling system provided, will last for many years as well. You just fill the embedded water tank with distilled water one time and check the levels quarterly.

Recommended Induction Heaters

Series 900 – Brazing of small-dimension diamond or hard-metal tools.

Series 200 – Localized brazing of medium-sized hard-metal tools.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service